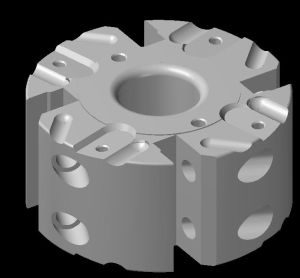

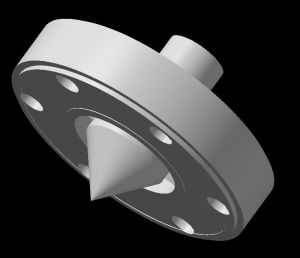

At Giriraj Industries we utilize the best technology in the market for 3D design and part/mould tool analysis software, to get your concepts into production as fast and efficiently as possible, reducing time to market while maximizing cost savings.

Using state of the art machining technology and wide range of tools, we offer following expert services to our valuable customers.

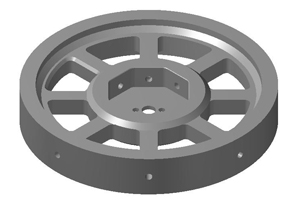

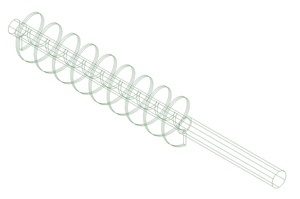

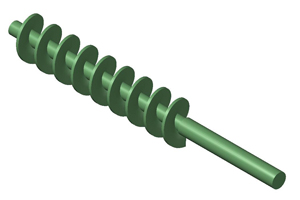

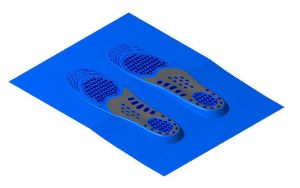

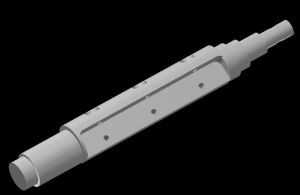

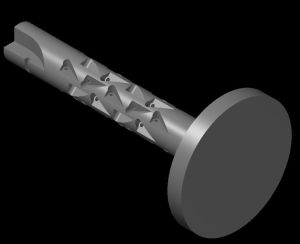

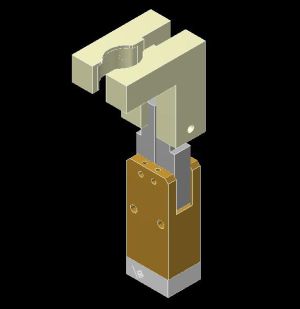

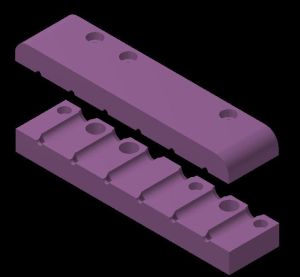

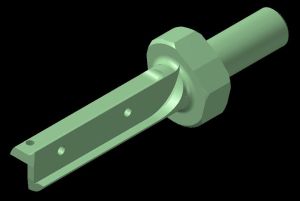

- Precision Machine Parts

- Precision Mechanical Assembly

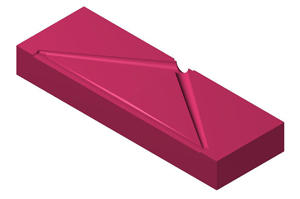

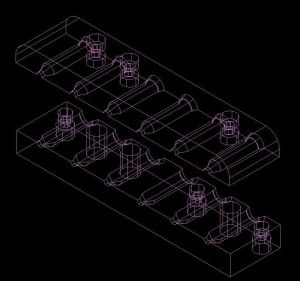

- PU Moulds

- Investment Casting Moulds

- Special Jig & Fixtures

- Injection Moulds

- Blow Moulds

- Progression Tools

- Inspection Fixtures

- Special Purpose Fixtures

Benefits:

Many years of industry experience with close networks of industrial specialists

Customized solutions using proven standards

Part analysis for manufacturing

Support through the entire process

Scheduled tracking reports issued frequently

Personnel involvement at every stage

Short manufacturing lead times - reduced time to market

Early identification of problems through the use of FEA software

Vast spectrum of tooling solutions that match product requirements and specifications

Features:

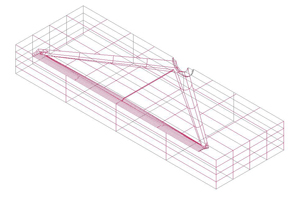

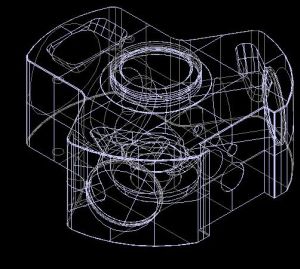

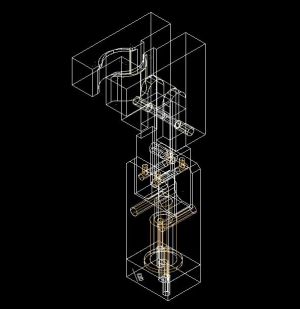

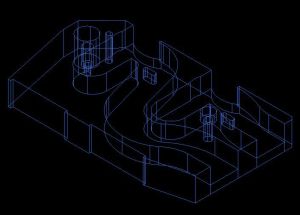

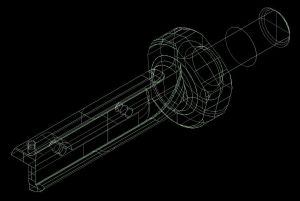

Leading 2D and 3D CAD design software

3D solid models used right through the manufacturing process in a total 3D environment

Finite element plastic part analysis

Part and mould optimization

Industry recognized

Project management software